Tel: +86-510-82829982 E-mail: sales02@ingksmetalparts.com

Professional. Focused. Wholehearted.

loading

| Availability: | |

|---|---|

| Quantity: | |

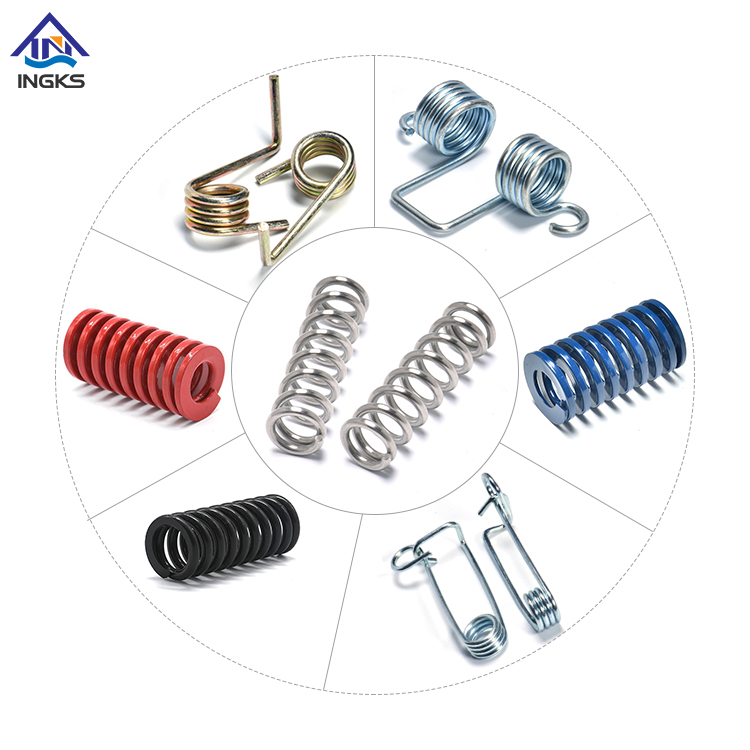

A coil spring is a helical-shaped mechanical device that is close-wound or open-wound. Coil springs store mechanical potential energy.

An important consideration for both compression springs and extension springs are their ends. Coil springs often are used with seats and grinding the ends flat allows them to set fully into a seat. This is especially true of heavy-duty springs such as those used in engine valve trains. Compression springs used for lighter duty applications will often just be made with single extra loops at the ends which lay flat compared with the spring helixes. Extension springs are available with many varieties of hooks and loops for their ends which serve as attachments to posts, holes, etc. Often the spring if overloaded will break at the hook, not the coil.

Materials for coil springs range from music wire to any number of spring steel alloys. Some materials offer good corrosion resistance, relaxation resistance, electrical conductivity, etc. Generally, coil springs are stress relieved after forming to remove any residual stresses imparted during the manufacturing process. For a more complete discussion on the different materials used in the manufacturing of springs, see our related guide on the types of spring materials.

A coil spring is a helical-shaped mechanical device that is close-wound or open-wound. Coil springs store mechanical potential energy.

An important consideration for both compression springs and extension springs are their ends. Coil springs often are used with seats and grinding the ends flat allows them to set fully into a seat. This is especially true of heavy-duty springs such as those used in engine valve trains. Compression springs used for lighter duty applications will often just be made with single extra loops at the ends which lay flat compared with the spring helixes. Extension springs are available with many varieties of hooks and loops for their ends which serve as attachments to posts, holes, etc. Often the spring if overloaded will break at the hook, not the coil.

Materials for coil springs range from music wire to any number of spring steel alloys. Some materials offer good corrosion resistance, relaxation resistance, electrical conductivity, etc. Generally, coil springs are stress relieved after forming to remove any residual stresses imparted during the manufacturing process. For a more complete discussion on the different materials used in the manufacturing of springs, see our related guide on the types of spring materials.